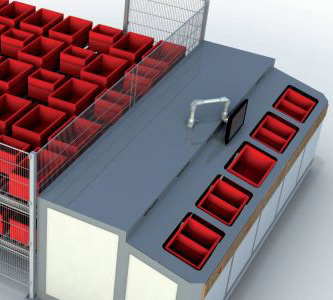

The ESP workstation for order picking is a station that uses the goods-to-man mode. It has been proven that this conceived and patent-protected design of processes and ergonomics, allows performances from 600 to 1,000 lines per hour in continuous operation.

EAP – High performance order picking station

In distribution logistics, we define it simply as: the customer receives the item he ordered, in the right quantity, at the right time, and undamaged. What may seem simple is actually a very complicated task, considering that hundreds or thousands of orders are sent daily and, therefore, millions of single processes are necessary, which leads to a large number of possible errors.

Good ergonomics is simple and self-explanatory. Ergonomics is certainly more than just being careful with your joints and muscles. It is also about logic, simple steps to be followed, and stress-free processes. In relation to the distribution center, this means, for example, optimizing search and guide tasks. Either there is only one removal position (which means there is no need for guidance), or the study of possible error of order picking lists is replaced by light indicators and PBL (pick-by-light) displays. Moreover, a good workstation is also smart. It “knows” the next most likely step, or the processes are not allowed at that particular time. For example, an order cannot be completed if a product falls into the wrong container.

There are three EAP principles, combined here to improve the quality:

- Reduction of the employee’s physical loads, thus reducing errors caused by fatigue;

- Reducing the number of errors in the process;

- This type of solution has the highest picking performance of all existing technologies. It will be, without any doubt, the best solution to your storage, picking, direct labor, error, order closing speed, high damage, etc. problems.

Increasing productivity in combination with quality support processes will almost automatically lead to an improvement in performance time. The more it can be done with less effort, there will be fewer error-related disturbances. This means that orders are filled more quickly. Less performance time is not an end in itself, but comes with important advantages. The entire warehouse is not only becoming more flexible, but also less occupied. Performance time reduction means that each order takes less time to be processed at the warehouse. Each order that is filled more quickly reduces the number of orders processed simultaneously and decreases the amount of pending orders in general. This reduces complexity at the warehouse and makes “hidden” performance reservations clearer and within reach.

This is what makes ergonomics a subject that is worked so much at BRINT®. Ergonomics does not only contribute to the welfare and relief of employees, but it also brings measurable and distinct advantages in productivity. Aside from this, improvement in quality results in less expenses due to errors related to this, and also leads to a greater consumer satisfaction which, in turn, is important for future business. Finally, ergonomics also enhances flexibility inside the warehouse, reduces complexity, and increases the order processing speed.