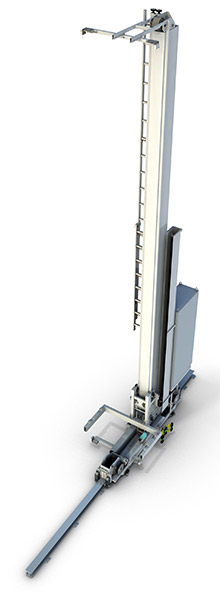

The Miniload System is an automated storage system for totes, cartons or trays. This system integrates, in a single product, the shelves, machines and the warehouse management system. It is formed by one or more aisles where one or more machines circulate, and by two shelves located on both sides for storing boxes or trays. On one end, or on one side of the shelf, the automated and handling area is located, formed by conveyors on which the Miniload deposits the good extracted from the dispatch shelf for order picking.

Miniload

Thanks to its versatility of applications, Miniload Systems meet the most varied types of operations, providing a sophisticated storage system and achieving greater density of stored products.

Characteristics:

- Based on the GTM (Goods-to-Man) principle, in which the product box is sent to the product picking station, integrated with HPPS – High Performance Picking System;

- Optimization of available storage spaces;

- Reduction of direct operating costs;

- Reduction of need of operators, pallet trucks, forklifts, computer system facilities, collectors and the like;

- Reduction in lighting and energy consumption costs;

- Reduction of investment in building construction, land acquisition and, consequently, reduction of expenses on municipal taxes (property tax);

- Automation of product input and output operations;

- Permanent real-time inventory;

- Elimination of manual warehouse management derived errors, deviations or damages;

- Maximum convenience and ease of access to stored boxes;

- Permanent inventory control, thus allowing for improvement in management of stocks and FIFO, FEFO and BATCH processes;

- Safe operation, high availability and low maintenance;

- High performance in difficult environments as well, as in the case of cold storage warehouses, handling of chemical products, etc;

- Integration and continuity of the supply chain from the total view of the processes;

- Absence of interruptions between flows and real-time management;

- Complete control of the efficacy levels of equipment involved through the Supervisory System.